A product can be of high quality but selling it efficiently becomes difficult if it is not packaged & presented well. Look of your product is something that attracts new customers and good looks can be ensured via fine packaging services. Packaging small quantities can be done manually in an efficient manner but if the amount of products to be packed is huge or if the number of items to be packed is many then it is better to go for automatic packaging processes.

Many kinds of machines are now available in the market that assists packaging. They help in automating your packaging process completely or to a certain extent (i.e. they can be completely automatic or semi-automatic). Packaging machines help your business in many ways including the following ones:

- It reduces time consumption

- It reduces effort needed to be invested

- It reduces errors and thereby increases efficiency

Reduces time consumption

Automation helps you in saving your valuable time. Invest the time you gained through automation in enhancing your core business. Let the packaging get done easily consuming lesser time of your employees (who can now do other jobs for you during the saved time).

Reduces effort needed to be invested

Effort also becomes less as minimal manual interruption is needed. Easy packaging processes increase employee satisfaction too.

Reduces errors and thereby increases efficiency

More chances of errors – like forgetting to keep the label, tampering the packages etc- occur when packaging is done entirely by people. But on the other hand automatic packaging services ensure lesser error and better quality of packaging – thereby increasing efficiency.

Saves money on a longer run

The use of machines that automate or semi-automate the packaging services helps you in saving money too on a longer run (apart from the initial investment). You save money on a daily basis on the wages of employees packaging products as automation helps you in doing the same packaging jobs with half or even lesser number of employees.

Types of packaging machines

Now as we understood the need of automation, let us take a look on the various kinds of packaging machines available in the market. 5 most important types of machines are:

- Filling machines

- Sealing machine

- Wrapping machines

- Strapping machines

- Labeling machines

Filling machines

These machines are used to fill products in the needed amounts into their corresponding containers. Precision in amount of product filled is the biggest quality offered by such machines. Most of the food and cosmetic industries needs such machines.

Sealing machine

Sealing machines are used for sealing the product-containers properly. Certain products – mainly food products (to prevent contamination and to ensure proper quality) – have to be sealed airtight. This job is done by the sealing machines without any flaw.

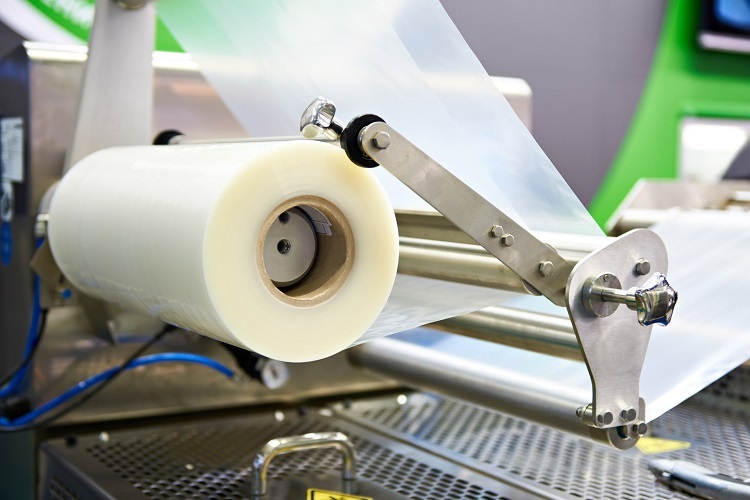

Wrapping machines

Wrapping machines are used mostly in layer packaging. Even three layer wrapping can be provided using these machines. Foil, paper or cellophane is used for wrapping. Soap, candy and razor blades are few examples of industries that use wrapping machines majorly.

Strapping machines

Strapping machines strap items to stabilize, combine, fasten or reinforce it. Many kinds of strapping machines suppliers are available in market. Some strapping machines are effective in strapping either soft materials or hard items. Newspaper industry is an example for the industry that needs strapping techniques to keep items together.

Labeling machines

Labeling has to be done perfectly without any error. It helps your customers in identifying the product details easily. Hence labeling machines can be considered as a must for any large scale industries that package products. You can find large number of quality labeling machine supplier in market.

The 5 basic and most important packaging machines given above helps you in automating your packaging process to a great extent (based on the kind of machine you choose). Access the help of such machines and make your packaging processes easy, fast and less error-prone. Lesser errors ensure higher quality and better customer satisfaction which thereby leads to business success.